The failure mode and effect analysis template is a well-known method which is aimed at providing assistance in determining the actual failure mode and its effects. Well, as per history, we can say that it was originally developed at the start of 1941 and the purpose was clear; to figure out the problems. This technique is officially derived by reliability engineers. However, we can also call this failure mode and effect analysis, which will be abbreviated as failure mode and effect analysis. No doubt, this is a typical sort of study method which is drafted by engineers when they are all set to launch a new product. Moreover, after the design phase of making some product or system, the engineers will conduct a failure mode and effect analysis that will shortly tell the aftereffect of a product that is going to be introduced in a market. Thus, once the team of analysts gets the positive results, the company will sell their products, programs or systems in the market.

Importance of Failure Mode and Effect Analysis:

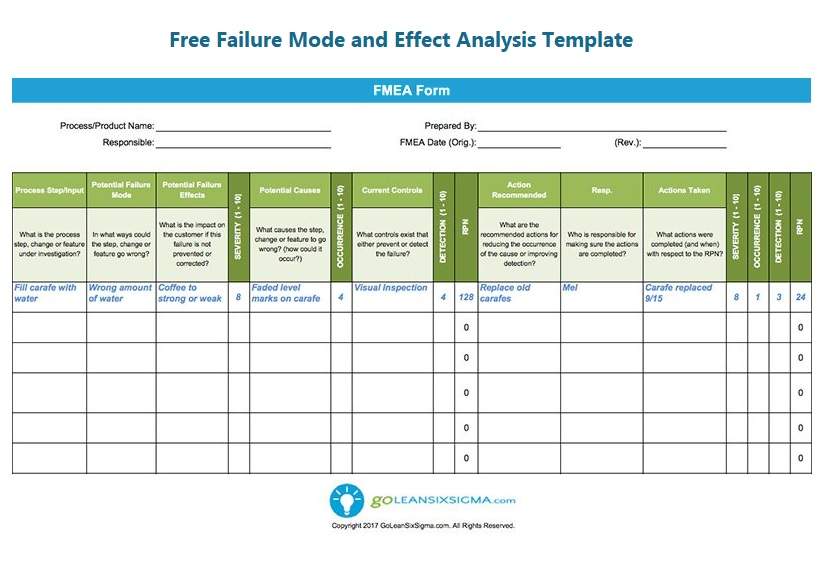

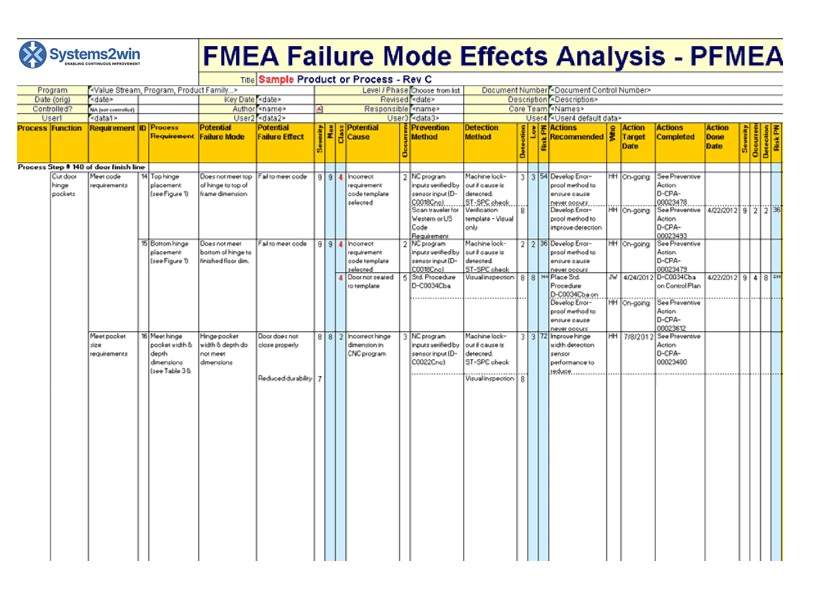

In the general scenario of manufacturing, there are almost entire industrial units that launch their new products after testing them on the tester of failure mode and effect analysis. From the point of view of engineering, after completing the design or in some such way, when design is near to the end, the employees of a company who are very familiar with the product will start the quality test using a systematic technique known as failure mode and effect analysis. In this process, the individual analyst will cover all the facts that belong to the potential failures of the product as well as their multiple positive or negative effects. While listing and discussing this technique, the professional analyst will aside the factors of failures and will also identify those areas where improvements are necessarily required. In addition, the vital purpose of this analysis is to get positive results and determine reasonable efforts to prevent failures along with identify the areas where improvement will help and modify construction methods to minimize failures.

Benefits of Failure Mode and Effect Analysis Template:

1. It provides a systematic approach not only for identifying the ways in which a systematic process fails before impacting the customer, but also locates the real issues in product functions. Moreover, it highlights substantial manufacturing failures as well as crucial variables in production while controlling errors to improve detection of failure conditions.

2. It helps in redesigning rational prioritization of potential failures in production or product development.

3. This system makes sure to identify condemnatory process values.

4. The purpose of this analysis is to enable a system which can identify crucial input for the controlled process.

5. It defines a system which can eliminate problems before rising in an organization’s production activities and routine.

6. Successful adoption of production procedures and effective production ramps.

7. Another benefit of this system is to reduce the cost of warranty, product development and manufacturing.

8. Once this system enables you to maintain high quality standards, then you might be able to provide higher customer satisfaction.

9. Apart from production and manufacturing, this analysis tool helps to select the proper team and organize members effectively.

10. Each team is required to operate on each process independently, which will encourage team members to work efficiently and productively.

11. With the help of a ranking system as recommended by this tool, quality of production or service can easily be improved.

12. For higher quality standards, usually this matrix recommends an organization to reduce the gap between customer needs and expectations. This process helps in identifying the true needs of customers and how your services or products can meet their expectations. Any improvement based on this matrix will certainly improve the quality standards.

13. In determination of a flawless system of production or manufacturing toward reducing cost and improving quality, this matrix helps in defining or redefining the whole process requirements.

14. A true modification to the overall system remapping process based on flow charts can only be possible with the help of this analysis tool.